ANEST IWATA SOUTHEAST ASIA Co., Ltd.

Our Japanese-standard quality products

Gas-Heated Hot Air Drying Oven CUG Series

LPG (liquefied petroleum gas) capable of generating a large amount of heat (12,000 kcal/kg) is used as a heat source. (The use of town gas is optional.)

Product Detail

Gas-Heated Hot Air Drying Oven CUG Series

LPG (liquefied petroleum gas) capable of generating a large amount of heat (12,000 kcal/kg) is used as a heat source. (The use of town gas is optional.)

Applications

- Drying painted workpiece

Features

Supports the after purge function as a standard feature.

- After the burner finishes its operation, the after purge function is activated to cool the interior of the oven.

- When the cooling is completed, the circulating fan automatically stops.

Easy to bring the workpiece in and out of the oven

- The doors open to their full width. You can put the workpiece on a carriage and bring the whole thing in and out of the oven.

- The oven has metal shelf supports inside for height adjustment.

Easy operation

- The control panel enables centralized control over drying temperature and time, burner operation, circulating fan operation, etc.

- Alarms are displayed as codes on the control panel.

- With the two-burner type, the parent-child relationship between the control panels can be established using a single communication line and all the operations can be done with one control panel. The parent and child panel can be operated individually by using a switch.

Stable oven temperature

- The hot air circulating system exerts microcomputer-based time-proportional control. What’s more, the oven has a wind direction adjusting gallery at the internal outlet as a standard component to keep the oven temperature within a certain range (±10℃).

- The CUG Series uses a dedicated gun-type burner with high ignition performance that is easy to maintain.

- The CUE Series uses a fin-equipped sheathed heater with high heat efficiency.

Fuel efficient and economical

- LPG (liquefied petroleum gas) capable of generating a large amount of heat (12,000 kcal/kg) is used as a heat source. (The use of town gas is optional.)

- An electric drying oven that is easier to install is also available.

Quick temperature rise

- The temperature in the oven rises quickly – it takes only 18 minutes to reach 200°C (CUG-444B) – resulting in greater work efficiency.

Dust-proof

- The fresh air inlet and the outlet inside the oven have filters to prevent dust from settling.

- Both interior and exterior plates are made of molten aluminum-zinc alloy-plated steel sheets. They are not painted and therefore do not generate dust.

Larger inner volume and smaller floor space

- Meter modules are used for the internal dimensions of the oven, increasing the inner volume by 23 to 25% for the CUG models and by 21 to 25% for the CUE models compared to the previous models.

- The hot air generation chamber and the operation panel are combined into a single slim unit.

Oven steel sheets separated from heat insulating material

- The oven is designed to be disassembled easily for recycling considerations.

- It is also easy to replace only the heat insulating material (glass wool).

Safety

- The oven comes equipped with a seismic detector, gas pressure switch, wind pressure switch, and ignition check relay.

- The ceiling panel has an explosion-proof outlet on its front side.

Main Functions

| Heat Source | Gas |

| Main Body Panel | Both interior and exterior plates are made of molten aluminum-zinc alloy-plated 1-mm-thick steel sheets. |

| Heat Insulating Material | 50-mm-thick glass wool board |

| Circulating Fan | Limit Load Fan; Totally-Enclosed-Fan-Cooled Motor |

| Temperature Setting | Room temperature + 50°C to max. 200°C (ambient temperature) |

| Type of Gas | LPG (Option: Town Gas) |

| Burner | Gun-Type Burner |

| Temperature Control Method | Time-Proportional Control |

| Safety Mechanism | Temperature controller (with high temperature alarm), gas pressure switch (high/low), wind pressure switch, fire detector, seismic detector |

| Drying Timer | Can be set to an arbitrary value between 1 and 999 minutes; equipped with a drying end buzzer (intermittent sound). |

| With the after purge function | |

| Alarm Buzzer | Indicates an alarm (continuous sound). |

| Emergency Stop | Gas shutdown by the alarm check circuit |

| Control Panel | Closed Type Controller Container |

Safety Mechanism

| Wind Pressure Switch | Monitors the amount of air necessary for the burner to burn and whether the circulating fan is operating normally in order to prevent incomplete combustion and empty burning. |

| Pre-Purge | The pilot burner does not ignite unless the circulating fan and combustion blower operate for 30 seconds to take fresh air into the combustion chamber. |

| Flame Rod | After the flame of the pilot is detected, the main gas valve of the burner opens to ignite. |

| Temperature Controller (with high temperature alarm) | Stops burner combustion automatically if the temperature inside the oven exceeds the set value. |

| Gas Pressure Switch | Monitors the gas pressure constantly and stops burner combustion automatically if the gas pressure becomes abnormally high or low. |

| Seismic Detector | Stops burner combustion automatically if an earthquake with an intensity of 5 or higher occurs. |

| Protection Relay | Core part of the burner circuit that exerts proper control over burner ignition |

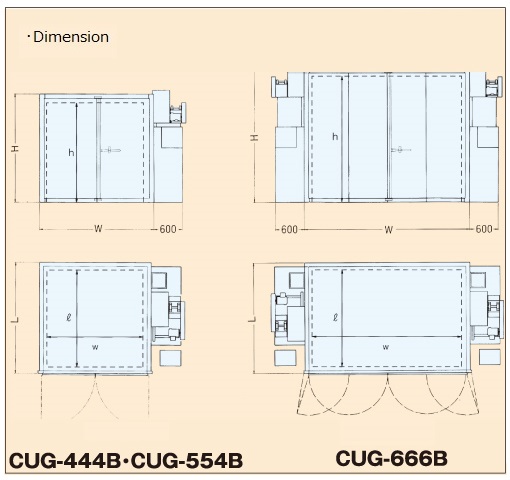

Dimensional Diagram

-1.png)