ANEST IWATA SOUTHEAST ASIA Co., Ltd.

Our Japanese-standard quality products

A diverse selection of Japanese-standard coating and spraying equipment suitable for general industry work, automobile parts manufacturing, electrical devices manufacturing, car body paint and spray works are available here. Our products help customers manufacture goods to their anticipated standards while having good quality work piece and being environment-friendly.

Product Detail

Wider1 Series

| Model | Previous Model | Type of feed |  |  |  |  |  | Atomization |  |  | Application |

|---|---|---|---|---|---|---|---|---|---|---|---|

| WIDER1-08E2P | W-101-082P | Pressure | 0.8 | 0.29 | 270 | 150 | 190 | High atomization | E2P | 290 | Car OEM, Wood and furniture, metals, plastics |

| WIDER1-10E2P | W-101-102P | Pressure | 1.0 | 200 | 220 | ||||||

| WIDER1-13E2P | W-101-132P | Pressure | 1.3 | 0.24 | 220 | 210 | Wood and furniture, metals, medium-viscosity paints Light industry, hobby | ||||

| WIDER1-15E2P | W-101-152P | Pressure | 1.5 | 250 | 240 | ||||||

| WIDER1-10E1G | W-101-101G | Gravity | 1.0 | 75 | 95 | 130 | General atomization | E1 | |||

| WIDER1-13K1S | W-101-131S | Suction | 1.3 | 145 | 150 | 155 | K1 | Auto Refinish, Wood and furniture, metals, plastics | |||

| WIDER1-13H2S | W-101-132S | Suction | 1.3 | 225 | 150 | 160 | High atomization | H2 | |||

| WIDER1-13H2G | W-101-132G | Gravity | 1.3 | 160 | 175 | ||||||

| WIDER1-15K1S | W-101-151S | Suction | 1.5 | 145 | 175 | 170 | High atomization | K1 | Wood and furniture, metals | ||

| WIDER1-15H2S | W-101-152S | Suction | 1.5 | 225 | 170 | 175 | High atomization | H2 | Auto Refinish, Wood and furniture, metals, Wood | ||

| WIDER1-15H2G | W-101-152G | Gravity | 1.5 | 190 | 190 | ||||||

| WIDER1-18N1G | W-101-181G | Gravity | 1.8 | 170 | 240 | 190 | General atomization | N1 | Wood and furnitures, metals |

Wider2 Series

| Model | Previous Model | Type of feed |  |  |  |  |  | Atomization |  |  | Application |

|---|---|---|---|---|---|---|---|---|---|---|---|

| WIDER2-12G2P | W-200-122P | Pressure | 1.2 | 0.29 | 500 | 500 | 400 | High atomization | G2P | 375 | Large parts and vehicles, line painting |

| WIDER2-15K2S | W-200-152S | Suction | 1.5 | 330 | 240 | 290 | High atomization | K2 | Auto Refinish, Wood and furniture, plastics | ||

| WIDER2-18K2S | W-200-182S | Suction | 1.8 | 330 | 290 | 340 | High atomization | K2 | |||

| WIDER2-20R1G | W-200-201G | Gravity | 2.0 | 260 | 410 | 280 | General atomization | R1 | Metals, Wood and furniture, medium viscosity paints | ||

| WIDER2-20R2S | W-200-202S | Suction | 2.0 | 360 | 350 | 290 | High atomization | R2 | |||

| WIDER2-20R2G | W-200-202G | Gravity | 2.0 | 140 | 320 | ||||||

| WIDER2-25W1S | W-200-251S | Suction | 2.5 | 360 | 440 | 280 | General atomization | W1 | Metals, Wood and furniture, anticorrosion treatment for steel frames, high-viscosity paints | ||

| WIDER2-25W1G | W-200-251G | Gravity | 2.5 | 510 | 310 |

WS-200SP

SPLIT NOZZLE

| Technical Data |  |  |  |  |

|

|---|---|---|---|---|---|

| WS-200SP-0801 | 0.8 | WS-200SP-01 | 200 | Spray Distance at 150 mm | 210 |

| WS-200SP-1001 | 1.0 | 250 | 230 | ||

| WS-200SP-1201 | 1.2 | 300 | 240 | ||

WS-200FT

FLAT TIP NOZZLE

| Technical Data |  |  |  |  |

|

|---|---|---|---|---|---|

| WS-200FT-0801 | 0.8 | WS-200FT-01 | 200 | Spray Distance at 150 mm | 240 |

| WS-200FT-1001 | 1.0 | 210 | |||

| WS-200FT-1201 | 1.2 | 210 | |||

| WS-200FT-0802 | 0.8 | WS-200FT-02 | 200 | 215 | |

| WS-200FT-1002 | 1.0 | 250 | 250 | ||

| WS-200FT-1202 | 1.2 | 300 | 255 | ||

W-61

| Model | Type of feed |  |  |  |

|---|---|---|---|---|

| W-61-0 | Pressure | 0.8 | 200 | 190 |

| W-61-1S | Suction | 1.0 | 95 | 100 |

| W-61-2S | Suction | 1.3 | 135 | 135 |

| W-61-3S | Suction | 1.5 | 160 | 185 |

| W-61-1G | Gravity | 1.0 | 110 | 120 |

| W-61-2G | Gravity | 1.3 | 155 | 155 |

| W-61-3G | Gravity | 1.5 | 190 | 220 |

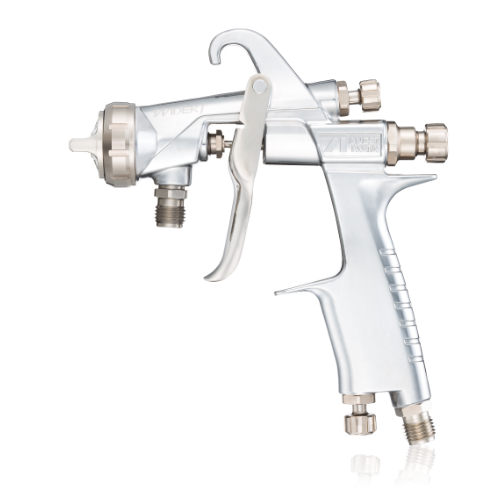

W-71

| Model | Type of feed |  |  |  |

|---|---|---|---|---|

| W-71-0 | Pressure | 0.8 | 200 | 190 |

| W-71-02 | Pressure | 1.0 | 300 | 265 |

| W-71-1S | Suction | 1.0 | 95 | 100 |

| W-71-2S | Suction | 1.3 | 135 | 135 |

| W-71-3S | Suction | 1.5 | 180 | 170 |

| W-71-21S | Suction | 1.3 | 140 | 155 |

| W-71-31S | Suction | 1.5 | 170 | 170 |

| W-71-4S | Suction | 1.8 | 195 | 195 |

| W-71-1G | Gravity | 1.0 | 110 | 120 |

| W-71-2G | Gravity | 1.3 | 155 | 155 |

| W-71-3G | Gravity | 1.5 | 210 | 185 |

| W-71-21G | Gravity | 1.3 | 160 | 165 |

| W-71-31G | Gravity | 1.5 | 190 | 185 |

| W-71-4G | Gravity | 1.8 | 220 | 220 |

W-77

| Model | Typr of feed |  |  |  |

|---|---|---|---|---|

| W-77-0 | Pressure | 1.2 | 480 | 445 |

| W-77-02 | Pressure | 400 |

||

| W-77-1S | Suction | 1.5 | 255 | 210 |

| W-77-11S | Suction | 260 |

||

| W-77-12S | Suction | 230 |

||

| W-77-2S | Suction | 2.0 | 345 | 255 |

| W-77-21S | Suction | 350 | 270 |

|

| W-77-3S | Suction | 2.5 | 435 | 280 |

| W-77-1G | Gravity | 1.5 | 285 | 230 |

| W-77-11G | Gravity | 290 |

||

| W-77-12G | Gravity | 255 |

||

| W-77-2G | Gravity | 2.0 | 290 | 290 |

| W-77-21G | Gravity | 335 |

||

| W-77-3G | Gravity | 2.5 | 485 | 330 |

LPH-50

LPH-80

WIDER4L

| Model | Type of feed |  |  |  |  |

|---|---|---|---|---|---|

| LPH-50-042G | Gravity | 0.4 | 8 | 40 | E2 |

| LPH-50-062G | Gravity | 0.6 | 25 | 60 |

|

| LPH-50-102G | Gravity | 1.0 | 55 | 100 | |

| LPH-80-044G | Gravity | 0.4 | 10 | 55 | E4 |

| LPH-80-064G | Gravity | 0.6 | 30 | 80 |

|

| LPH-80-084G | Gravity | 0.8 | 45 | 100 |

|

| LPH-80-104G | Gravity | 1.0 | 60 | 130 |

|

| LPH-80-124G | Gravity | 1.2 | 75 | 140 |

| Model | Type of feed |  |  |  |  |

|---|---|---|---|---|---|

| WIDER4L-V13J2 | Gravity | 1.3 | 110 | 280 | WIDER4L-J2 |

| WIDER4L-V14J2 | 1.4 | 130 | 290 |

||

| WIDER4L-V16J2 | 1.6 | 150 | 300 |

RG-3L

| Model |  |  |  |

|---|---|---|---|

| RG-3L-1 | 0.4 | 15 | 25 |

| RG-3L-2 | 0.6 | 35 | 35 |

| RG-3L-3 | 1.0 | 80 | 35 |

HW-Series

| Model |  |  |  |

|---|---|---|---|

| HW-2001-25 | 2.5 | - | - |

| HW-2001-30 | 3.0 |

||

| HW-2003-20 | 2.0 | 300-400 |

SGD-71

| Model |  |  |  |

|---|---|---|---|

| SGD-71 | 0.7 | 80 | - |

Air duster AG-6

| Model |  |  |  |

|---|---|---|---|

| AG-6 | 1.7 | - | - |

| AG-61 |

|||

| AG-4B | 4.5 | ||

| AG-41B |

Suction feed container

PC-1

PC-2

PC-3

PCL-7B-2

PCL-10B-2

| Model | Capacity (m) | Mass (g) | Connection | Application spray gun |

|---|---|---|---|---|

| PCL-7B-2 | 700 | 370 | G1/4 (PF1/4) | W-101, -71, -61, LPH-101 |

| PCL-7B-3 | 700 | 375 | G3/8 (PF3/8) | W-200, -77 |

| PCL-10B-2 | 1000 | 410 | G1/4 (PF1/4) | W-101, -71, -61, LPH-101 |

| PCL-10B-3 | 1000 | 415 | G3/8 (PF3/8) | W-200, -77 |

| PC-1 | 1000 | 335 | G3/8 (PF3/8) | W-200, -77 |

| PC-1S | 1000 | 330 | G1/4 (PF1/4) | W-101, -71, -61, LPH-101 |

| PC-2 | 600 | 270 | G1/4 (PF1/4) | W-101, -71, -61, LPH-101 |

| PC-3 | 400 | 180 | G1/4 (PF1/4) | W-101, -71, -61, LPH-101 |

Gravity feed cup (Side)

PC-4

PC-5

PC51

| Model | Capacity (m) | Mass (g) | Connection | Application spray gun |

|---|---|---|---|---|

| PC-4 | 400 | 180 | G3/8 (PF3/8) | W-200, -77 |

| PC-4S | 400 | 168 | G1/4 (PF1/4) | w-50, -101, LPH-50, -101, W-71, -61, RG-3L |

| PC-400SB-2LTF | 400 | 210 | G1/4 (PF1/4) | w-50, -101, LPH-50, -101, W-71, -61, RG-3L, free-angle stainless steel cup fluorine-coated |

| PC-400SB-2LF | 400 | 210 | G1/4 (PF1/4) | w-101, LPH-101, W-71, -61, free-angle stainless steel cup |

| PC-250SB-2LF | 250 | 170 | G1/4 (PF1/4) | w-50, -101, LPH-50, -101, W-71, -61, RG-3L, free-angle stainless steel cup fluorine-coated |

| PC-5 | 250 | 135 | G1/4 (PF1/4) | w-50, -101, LPH-50, -101, W-71, -61, RG-3L |

| PC-51 | 220 | 126 | G1/4 (PF1/4) | w-50, -101, LPH-50, -101, W-71, -61, RG-3L, Stainless steel cup |

| PCG-6P-2 | 600 | 220 | G1/4 (PF1/4) | W-101, LPH-101, W-71, -61 Plastic cup |

| PCG-2P-3 | 600 | 227 | G3/8 (PF3/8) | W-200, -77 plastic cup |

Gravity feed cup (Center)

PC-G400-2

PCG-2D-1

PCG-2P-2

| Model | Capacity (m) | Mass (g) | Connection | Application spray gun |

|---|---|---|---|---|

| PCG-6P-M | 600 | 160 | M16 X 1.5 (female) | W-400, LPH-400 plastic cup |

| PCG-2P-2 | 200 | 100 | G1/4 (PF1/4) | W-300, LPH-300 plastic cup |

| PCG-2D-1 | 150 | 150 | G3/8 (PF3/8) | LPH-80, Aluminium cup |

| PC-G400P-2 | 400 | 158 | G1/4 (PF1/4) | W-300, W-300WB, LPH-300 plastic cup |

Pressure feed container

PC-18D

PC-19B

| Model | Capacity (m) | Mass (g) | Connection | Application spray gun |

|---|---|---|---|---|

| PC-17R | 400 | 564 | G1/4 (PF1/4) | SGS-71 disheveled gun Max. operating pressure 0.20MPa (2kgf/cm2/28.4psi) |

| PC-18D | 2000 | 1250 | G3/8 (PF3/8) | various spray guns Max. operating pressure 0.34MPa (3.5kgf/cm2/49.8psi) |

| PC-18DT (fluorine-coated) | 2000 | 1200 | G3/8 (PF3/8) | various spray guns Max. operating pressure 0.34MPa (3.5kgf/cm2/49.8psi) |

| PC-19B | 1000 | 470 | M16 X 1 (female) | W-2001-1 W-2003 Max. operating pressure 0.49MPa (5kgf/cm2/71.1psi) |

| PC-19R | 1000 | 830 | G3/8 (PF3/8) | W-200 W-77 Max. operating pressure 0.27MPa (2.8kgf/cm2/39.8psi) |

WIDER1L Series

| Model | Previous Model | Type of feed |  |  |  |  |  | Atomization |  |  | Application |

|---|---|---|---|---|---|---|---|---|---|---|---|

| WIDER1L-12G2P | LPH-101-122P | Pressure | 1.2 | 0.34 | 530 | 350 | 270 | High atomization | WIDER1L-2 | 290 | Mwtal, Wood and resin |

| WIDER1L-12J2S | LPH-101-124LVS | Suction | 1.2 | 0.1 | 200 | 60 | 170 | WIDER1L-2-J2 | Wood and furniture, metals | ||

| WIDER1L-14J2S | LPH-101-144LVS | Suction | 1.4 | 80 | 180 | ||||||

| WIDER1L-16J2S | LPH-101-164LVS | Suction | 1.6 | 95 | 190 | ||||||

| WIDER1L-12J2G | LPH-101-124LVG | Gravity | 1.2 | 80 | 200 | Automation refinishing, Wood, furniture and metals | |||||

| WIDER1L-14J2G | LPH-101-144LVG | Gravity | 1.4 | 130 | 220 | ||||||

| WIDER1L-16J2G | LPH-101-164LVG | Gravity | 1.6 | 0.13 | 240 | 100 | 220 |

WIDER2L Series

| Model | Previous Model | Type of feed |  |  |  |  |  | Atomization |  |  | Application |

|---|---|---|---|---|---|---|---|---|---|---|---|

| WIDER2L-10G2P | New Model | Pressure | 1.0 | 0.2 | 470 | 300 | 250 | High atomization | WIDER2L-G2 | 375 | Large parts and vehicles, Line painting |

| WIDER2L-12G2P | LPH-200-122P | 1.2 | 500 | 300 | WIDER2L-2-G2 | ||||||

| WIDER2L-14G2P | New Model | 1.4 | 500 | 300 | |||||||

| WIDER2L-2-10G2P | New Model | 1.0 | 430 | 130 | 280 | ||||||

| WIDER2L-2-12G2P | New Model | 1.2 | 150 | 300 |

-1.png)