We are grateful to our customers for 30 years of patronage

It has been 30 years since we launched the world’s first full-scale oil-free scroll compressor.

Our scroll compressor is currently the most widely used in the world, thanks to its strong reputation as a clean-air, low-noise, energy-saving device. In appreciation of your patronage, we have prepared a small gift for you. Details of the campaign can be found at the bottom of this page. We look forward to your continued patronage.

It really is an amazing

scroll compressor

WORLD’S BEST OF SEVEN

01

First Development in the world

First Development in the world※

Kazuaki Sato, a member of our Advanced Technology Laboratory who was involved in the development of the scroll from start-up to launch as a young member of the scroll development project team, tells the story behind the creation of the scroll compressor.

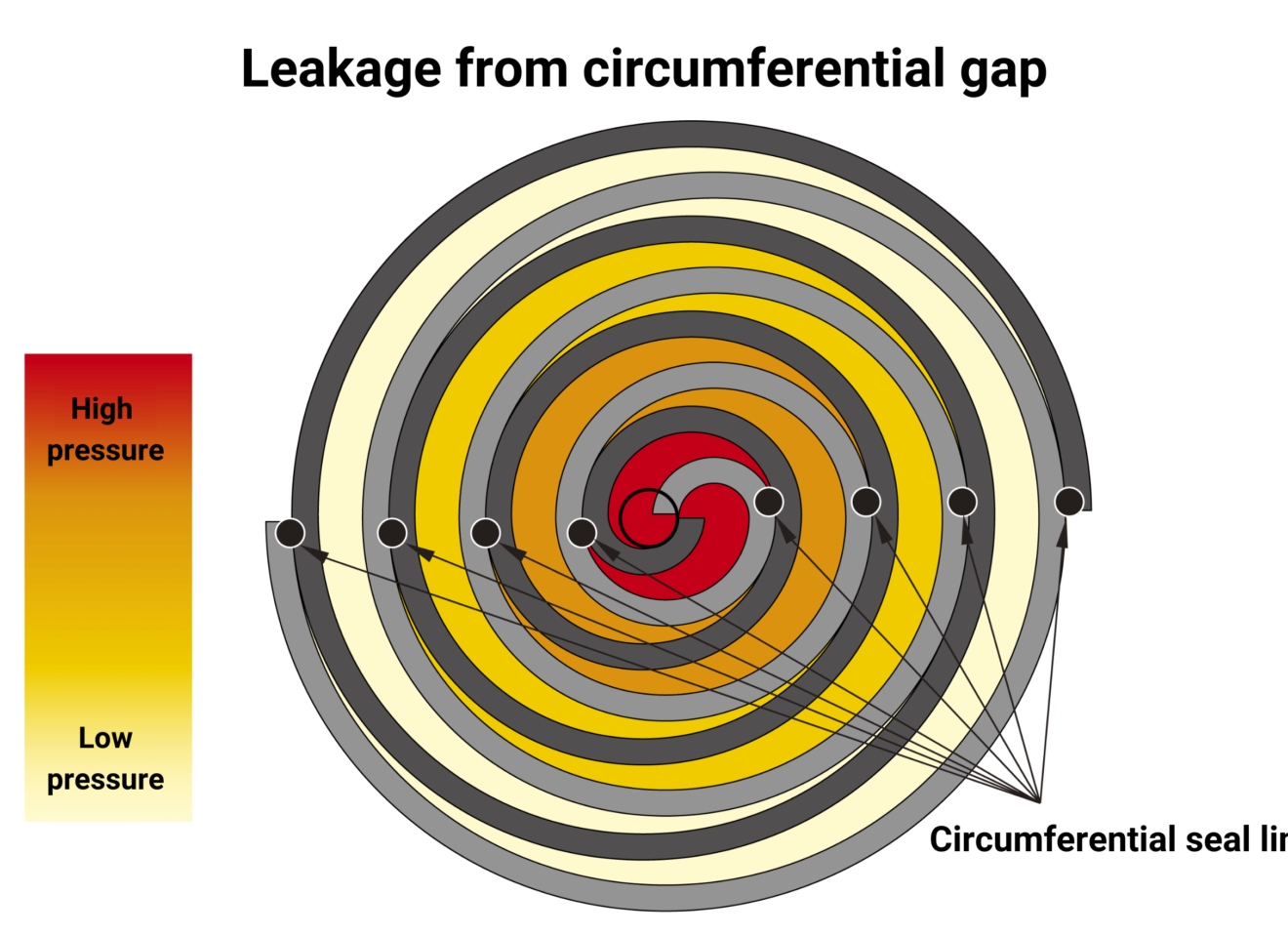

In this structure, multiple crescent-shaped air pockets and contact seal lines are formed on both sides from the suction (outer circumference) to the discharge (core); the air pockets gradually become smaller as they move to the center, resulting in compression. The gap between each sealing line is as long and narrow as one hair, and the pressure difference between the pockets is small, so leakage is difficult and the structure has a good pressure balance.

Q: Why did you choose the scrolling mechanism, and what were you trying to achieve with it?

At that time, industrial-use oil-free compressors were considered too expensive and had a number of problems, such as with inferior functionality and less durability than oil-lubricated compressors. General-purpose use of scroll compressors was rare in those days. Our policy is to create a different kind of oil-free compressor, so the scroll compressor development project was initiated with the idea of creating an oil-free device with low noise, low vibration, compactness, and the potential to overcome those problems. When we first started development, we were at the stage of making the scrolling mechanism oil-free, but we did not think that we had the most suitable mechanism for oil-free operation. What makes oil-free devices optimal is that they do not use oil, so the seal can be either a non-contact seal in a narrow space or a contact seal made of wear-resistant resin. Leakage from gaps and gap control are issues for non-contacting seals, while seal material wear is an issue for contact-type seals.

The scroll mechanism is then constructed to minimize leakage through of the following measures:

1) The seal line of the compression chamber is very narrow (about the width of a hair).

2) This seal line can be lengthened.

3) Multiple seal lines can be established in the scroll mechanism.

4) Minimal pressure difference between the high and low pressure sides makes leakage difficult.

Furthermore, the swivel motion makes for slow sliding speed and low pressure, so wear can be kept to a minimum. The optimal combined use of a non-contact seal, a contact seal, and swivel motion enabled us to realize a durable oil-free compressor with low noise, low vibration, compact size, and high performance, but we had to overcome a lot of challenges on the way to achieving that.

Q: How did you overcome these challenges?

None of us had ever undertaken such development before, and we had nothing to refer to, so we were mostly engaged in exploration. One of the most difficult tasks was to create the scroll’s unique swirling motion. We devised the world’s first pin crank mechanism to achieve stable swirling motion with high precision, which was difficult using the oil-free type at that time. In addition, we were able to add a mechanism that allows easy adjustment of the clearance of the swivel scroll, which is the greatest invention in oil-free technology, because had we not succeeded in that, progress would not have been possible.

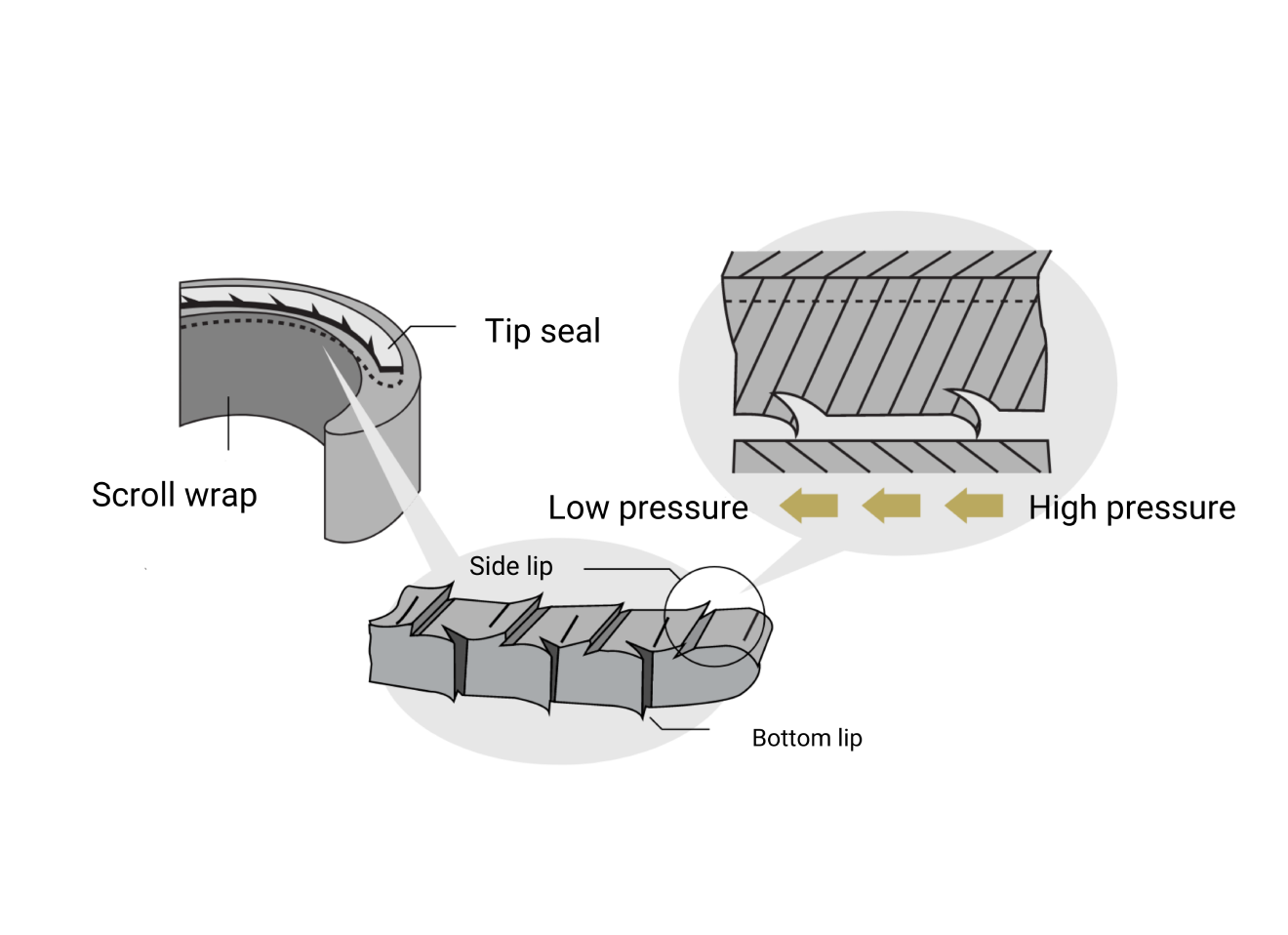

Next is the “chip seal with lip attached.” The chip seal is a contact seal that traps compressed air. In oil-free compressors, the oil has no sealing effect, and the materials used in the oil-free compressors in the past were unstable and ineffective, causing the seal to wear out quickly. We tried a number of prototypes in order to increase sealing efficiency and improve overall efficiency, but having found no success we had reached an impasse. As shown in the figure, small notches (lips) were made at intervals a few millimeters apart, which created a pressure differential between the lips. The differential pressure pushes up all the lips, which resemble fish scales, dramatically increasing the sealing effect and creating a stable seal.

In order to solve the problem of abrasion, we developed several types of abrasion-resistant resins in cooperation with materials manufacturers. We then searched for the optimum surface roughness for the contact surface, and after many severe endurance tests, we achieved a durability of 10,000 hours.

scroll’s swirling motion

Tip seal with lip attached (lip)

Q: What were some of the challenges and difficulties in the development process?

One of the difficulties we faced was that the planned development period had already been exceeded, with five years having passed.

Although we were well underway toward our aim of commercializing the product, we had to make a decision whether to launch the product or not since the extended development deadline had arrived again, despite the fact that we could not eliminate the problem of variable quality. After much discussion within the project, we finally decided to extend the development period by one year. We were able to launch the product after a series of verifications that resolved our concerns about uneven quality. This helped us prove that the product was reliable, with no major problems arising after the launch.

※This is based on our research of oil-free scroll compressors for industrial use of 0.75 kW or more, and oil-free scroll vacuum pumps for industrial use of 0.1 kW or more.

02

GLOBAL SUPPLY

Top global production and sales volume※

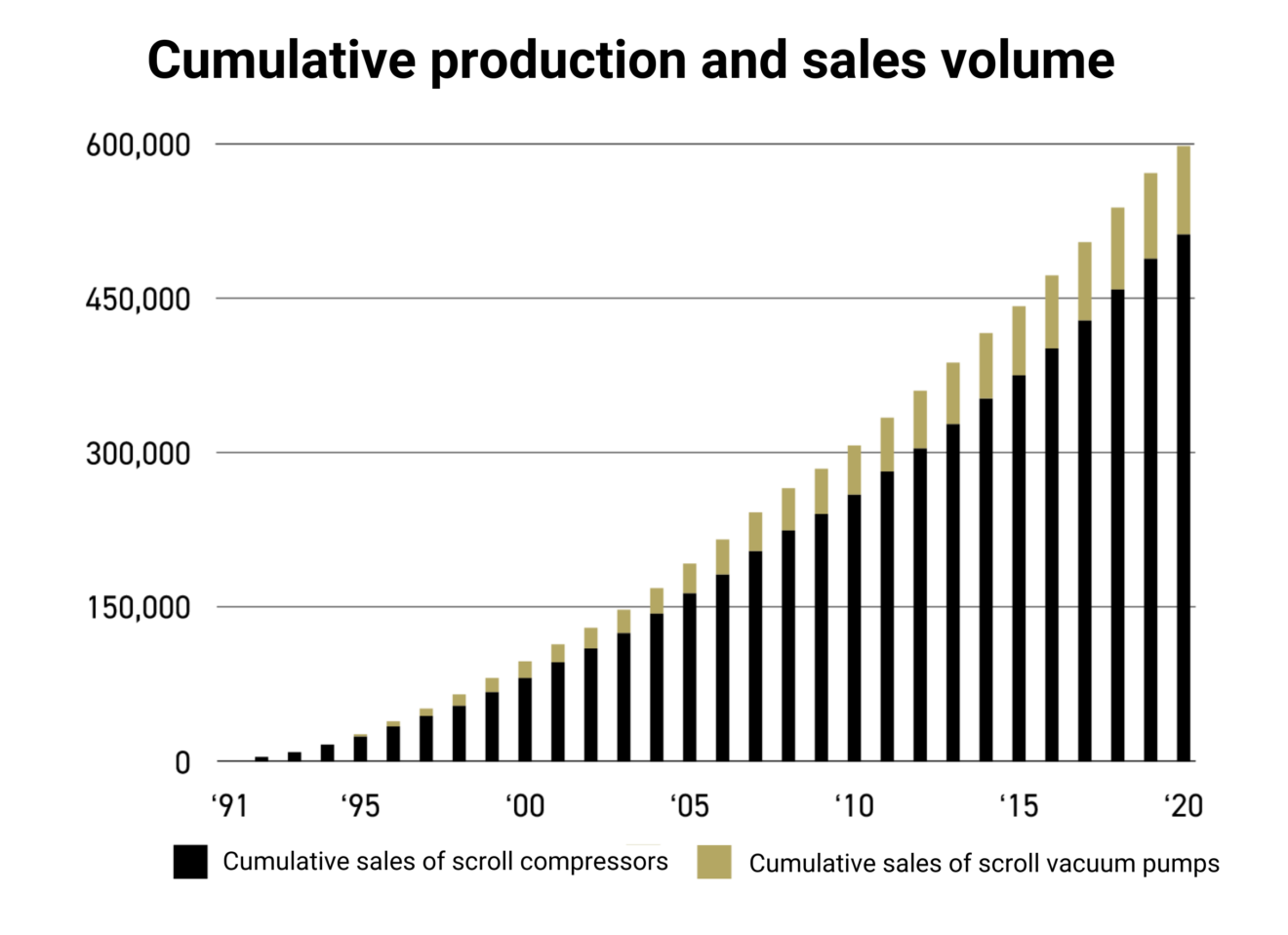

Since the development of the world’s first scroll compressor in 1991, we have continuously maintained the top market share for the past 30 years, steadily growing every year (as shown in the graph). Thanks to our customers, we have sold more than 550,000 units in total. In the meantime, we have been building up our manufacturing and sales bases in Europe, North America, South America, China, South Korea, and Southeast Asia (please refer to the map), and are now supplying our scroll compressors to customers in almost all major regions of the world. We would like to thank our customers for using so many of our scroll compressors over the past 30 years. We extend our deepest gratitude to all of our customers around the world for their patronage. We will continue to improve the quality and reliability of our products, and will continue to evolve so that our customers can be even more satisfied.

※This is based on our research of oil-free scroll compressors for industrial use of 0.75 kW or more, and oil-free scroll vacuum pumps for industrial use of 0.1 kW or more.

03

RYOGA

World’s fastest automatic assembly※ / World’s highest level of quality※

Q: Please tell us about the background of the introduction of RYOGA.

The oil-free scroll compressor, which has been on the market since 1991, has been used not only in Japan but also all over the world and has become one of the standards for compressors. A scroll compressor is a product that requires great precision at units of a few microns, like a hair’s breadth.

Our scroll compressors have since their launch been meticulously assembled by skilled craftsmen with a keen sense of precision.

However, given the trend of the times and the future decline in the number of industrial workers, we cannot rely on the hands of professionals forever. In addition, when the production volume became too great, human resources were gathered from within the company to handle the situation as a kind of human-wave tactic, which inevitably resulted in uneven work maturity and a slight difference in quality.

As one of our business models is to accept orders on the same day and ship them on the same day, scroll compressors require high quality and stable production at all times. The “RYOGA” automatic assembly device is designed to achieve high quality and uniformity by fully automating the “sense of the craftsman’s hands

Q: Please tell us about the difficulties you faced in automating the assembly process, which was previously left to the skills of craftsmen.

As with any product, the oil-free scroll compressor is particularly sensitive to the fact that reliable performance cannot be achieved without reliable accuracy in the production process.

For example, precise combination of the two spiral laps, which are essential parts of the scroll compressor, requires micron-level control of flatness and equilibrium, and the torque values of the bolts and plastic deformation of the materials to adjust these were previously manufactured using the sensitivity of human hands. However, with RYOGA, we have been able to maintain micron-level accuracy by using our own calculation formula based on the senses of our craftsmen.

The most difficult aspect of the project was to make the micron-level assembly work, which had been done by hand, into an algorithm that could be calculated and automated. It was a daunting task to calculate each individual assembly step for tens of thousands of units, add individual differences, and then program them.

The second item is that when you look at the compressor vertically, there are three pin crank shafts and one more shaft in the center, for a total of four shafts, but until then our craftsmen had been using only the senses of their hands to align all the shafts concentrically, inserting the shafts into the bearings and turning them while collecting the shafts in the center. It was particularly difficult to automate this task of “gathering the axes to the center while turning.”

Q: Have there been any on-site changes since the introduction of RYOGA?

In 2020, due to the severe situation caused by the corona turmoil, it may have been difficult to maintain quality, secure a stable production volume, and ship products on time with a production system that relies on human resources as before. I am very happy that RYOGA has enabled us to secure a stable production volume that does not depend on human resources and to improve the quality of our products by assembling them with an accuracy that is an order of magnitude better than that of skilled workers. We will continue to make every effort to produce and provide our customers with highly reliable scroll compressor products.

Based on our own research of industrial-use oil-free scroll compressors of 0.75kW or more.

04

LINE UP

The world’s most comprehensive product lineup※

Market penetration of scroll products has increased since their launch, so we have expanded our product lineup to meet market demand for a larger output range and higher pressure. In 1993, we developed the world’s first dry scroll vacuum pump, and have been working to expand its output range. We have also developed and introduced high output-range compressors and multi-unit compressors to expand our lineup. In the future, we plan to continue to expand our lineup of new products based on our proprietary technologies.

※ This is based on our research of oil-free scroll compressors for industrial use of 0.75 kW or more, and oil-free scroll vacuum pumps for industrial use of 0.1 kW or more.

Scroll Air End (0.75kW-7.5kW, 0.8MPa and 1.0MPa, 8 models)

SL-140EB

SL-105EF

SLー210

| Model | Motor rated output (kW) | Max pressure (MPa) |

|---|---|---|

| SL-105EF | 0.75 | 0.8 |

| SL-140EB | 1.5/2.2 | 0.8/1.0 |

| SL-165E | 3.7 | 0.8 |

| SL-1651E | 3.7 | 1.0 |

| SL-205 | 5.5 | 0.8 |

| SL-2051 | 5.5 | 1.0 |

| SL-210 | 7.5 | 0.8 |

| SL-2101 | 7.5 | 1.0 |

Scroll Compressor (0.75kW-30kW, 47 models)

SLPA-07

SLPA-110E

SLPA-300

*You will need to register in order to download the electronic catalog.

Vacuum pumps (0.1kW-2.4kW, Pressure 1-750Pa, 11 models)

ISP-250E

ISP-1000E

DVSLー500E

| Model | Motor rated output (kW) | Pressure (Pa) | Speed (L/min) |

|---|---|---|---|

| ISP-50 | 0.1 | 10 | 60 |

| ISP-90 | 0.15 | 5 | 108 |

| ISP-250E | 0.4 | 1.6 | 300 |

| ISP-500C | 0.6 | 1 | 600 |

| ISP-1000E | 1.4 | 1 | 1200 |

| DVSL-100C-B | 0.3 | 50 | 120 |

| DVSL-500E | 1.1 | 30 | 516 |

| DVSL-1002E | 2.4 | 30 | 1024 |

| GVS-250 | 0.75 | 750 | 255 |

| GVS-500E | 1.2 | 500 | 512 |

| GVS-1000E | 2.2 | 500 | 1031 |

05

SILENT

World’s most quiet-running compressors※

Unparalleled quietness

Our oil-free scroll compressor is one of the best in the world because of its low noise level and low torque fluctuation.

This year, we released a new model that is even more silent. As we celebrate our 30th anniversary, we continue to evolve.

※This is based on our research of oil-free scroll compressors for industrial use of 0.75 kW or more.

06

ENERGY SAVING

World’s highest energy efficiency※

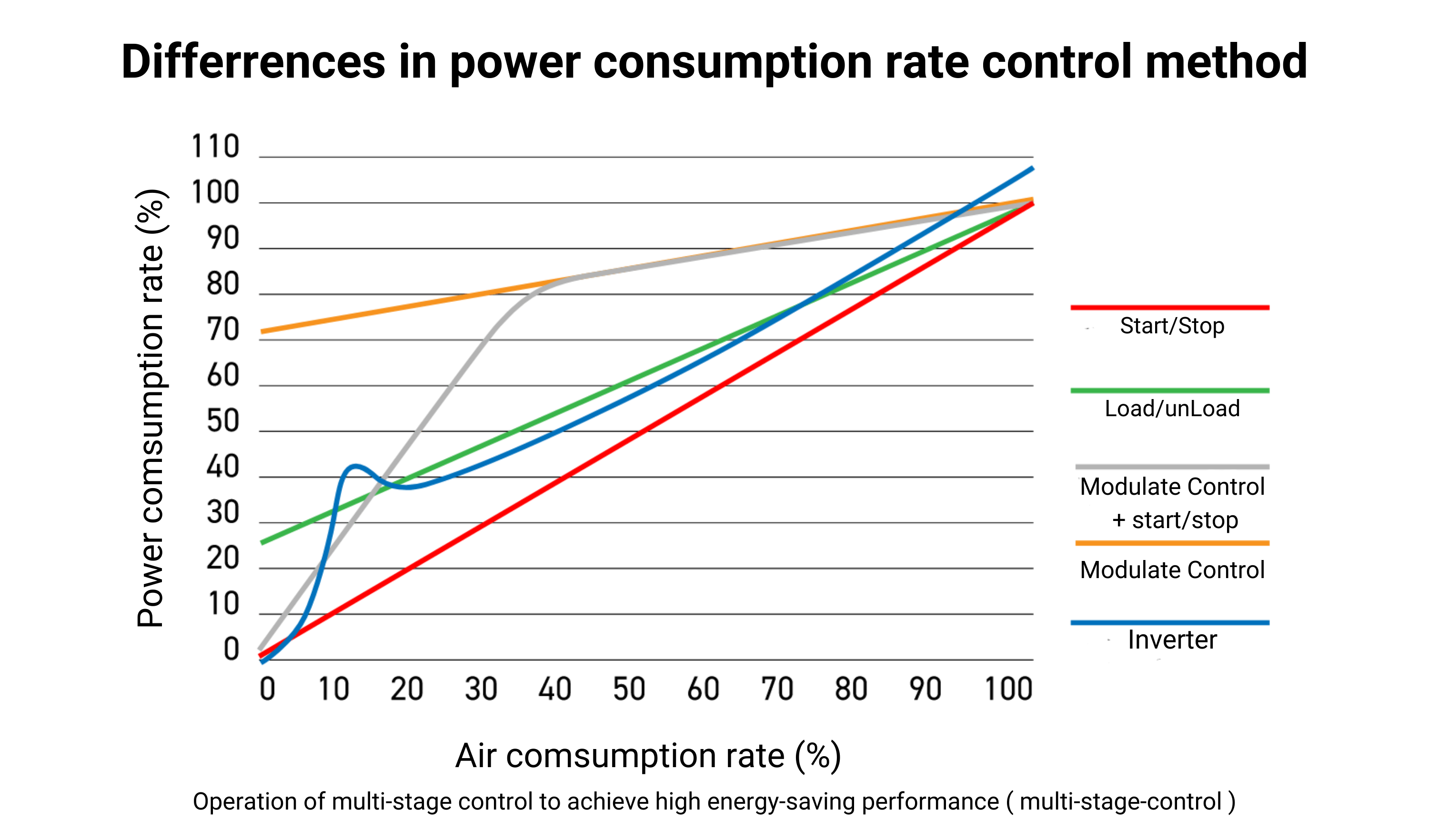

Superior energy saving controls.

Stopping compressors saves energy

The number of compressor units installed on the system is adjusted according to the amount of air used by the customer, and unneeded compressor units are stopped to reduce electricity costs as much as possible.

We developed and created the multiple-unit system because we noticed that by utilizing features identified during the development of the scroll compressor, such as “low vibration, easy start-up, compact size, and no need for peripheral equipment to maintain the scroll’s main functions,” this multi-unit system could perform in ways that are difficult using other compressors. Also, this multiple-unit system not only brings great benefits to the customer, but also has merit in terms of development and production.

At the time of its development in the 1980’s, there was not much demand for environmentally friendly compressors. However, since the beginning of its development, we have been conscious of the fact that in the future, awareness of low noise, low vibration, clean air, energy saving and maintenance free would surely evolve. Therefore, the scroll compressor continues to evolve as an environmentally friendly compressor that can contribute to the promotion of the Sustainable Development Goals (SGDs).

※ This is based on our research of oil-free scroll compressors for industrial use of 0.75 kW or more.

Customer Benefits

01 Energy efficiency

In the case of multi-unit systems, the control system operates the appropriate number of units according to the amount of air used by the customer, and stops the units that are not needed in order to reduce electricity costs as much as possible.

02 Backup function

Multiple compressor units are installed, so if one fails, other compressors can back it up.

03 Basic Features of Scroll Compressors

Low noise, low vibration, clean air, easy maintenance

Benefits to development and production

01 Easy to develop a high power compressor

There is no need to develop a new bigger air-end, and multiple air-ends can be used to develop bigger compressor.

02 Significantly increases the mass production effectiveness of the scroll unit

07

CLASS ZERO / CLEAN AIR

World’s highest standard of clean air※

Clean

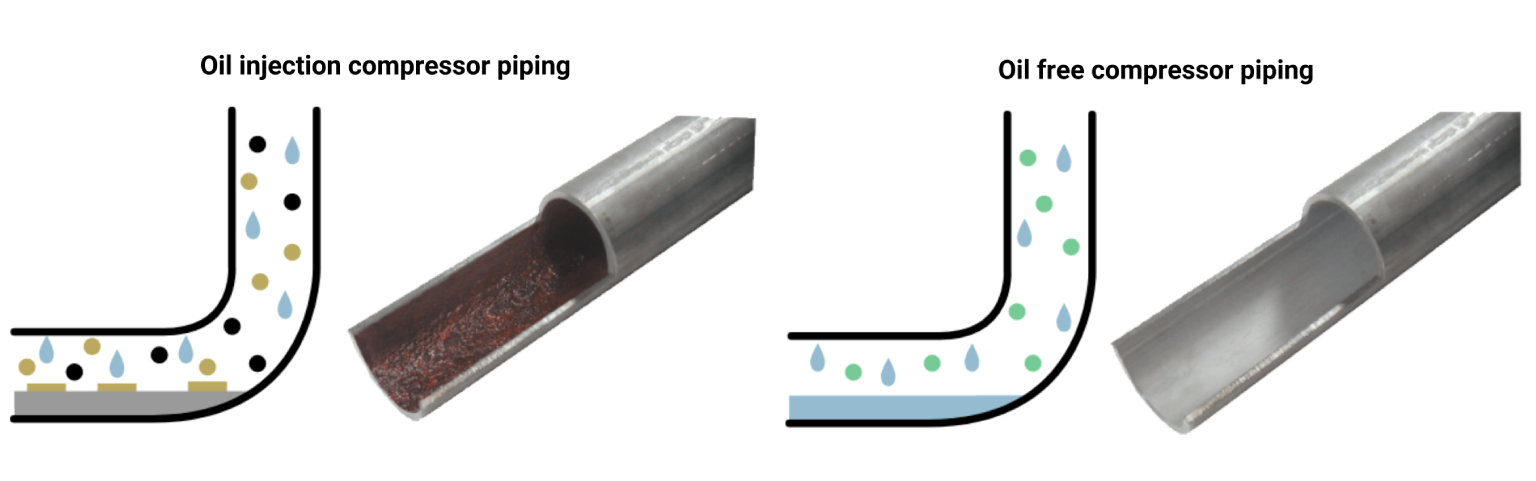

The compressed air produced by the oil supply type compressor contains oil. This oil will adhere to the inner surface of the pipes and foul them.

The clean air produced by the oil-free scroll compressor supplies high quality air to the factory without contaminating the internal surfaces of the pipes.

Class Zero Certification

Our oil-free scroll compressor has been certified by TUV, a German international certification organization, as having “Class 0” compressed air quality (ISO 8573-1:2010[-:-:0]).

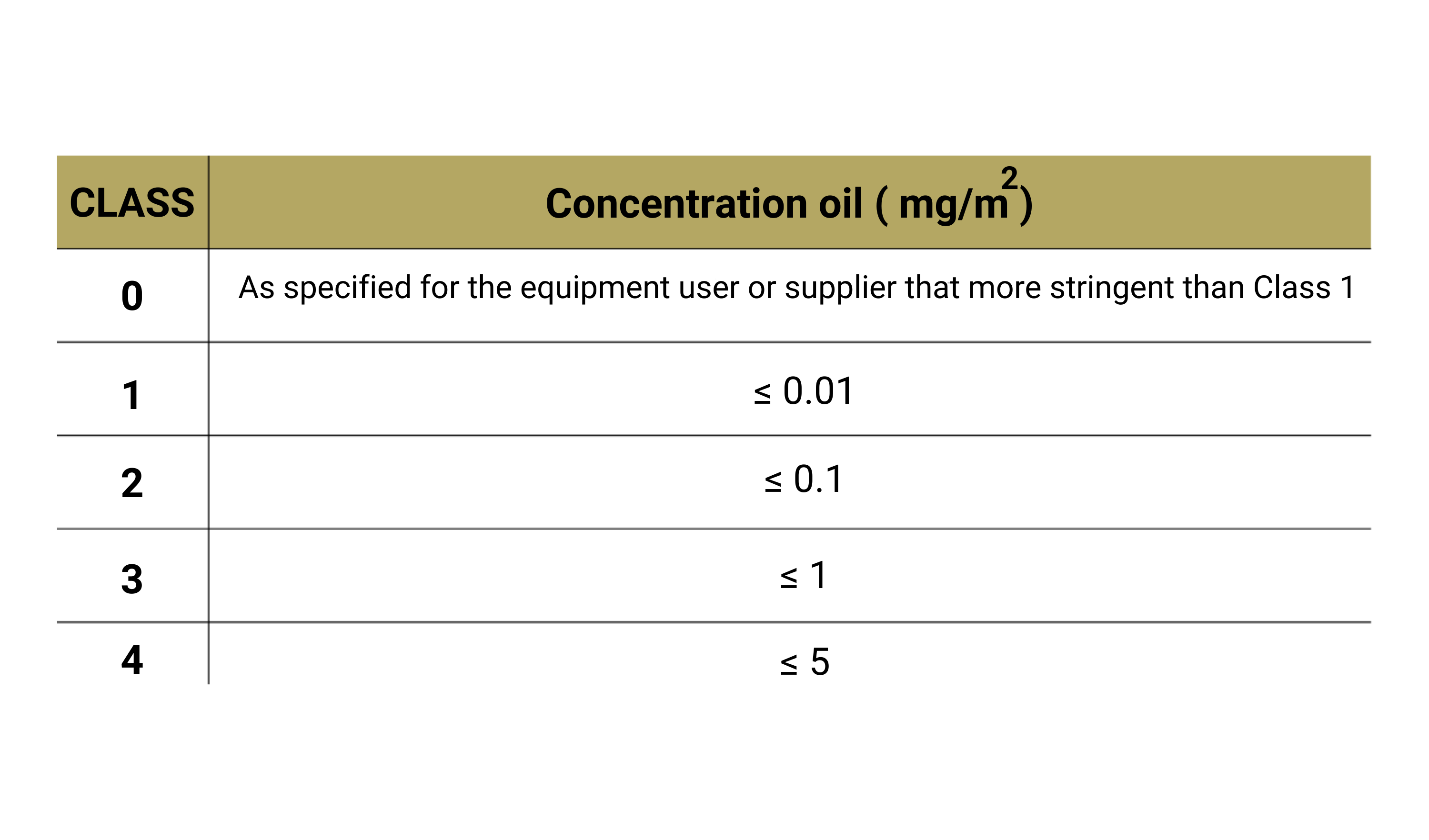

What is Class Zero?

Compressed air quality class, which measures the cleanliness of compressed air, is established by ISO 8573-1 (JISB 8392-1).

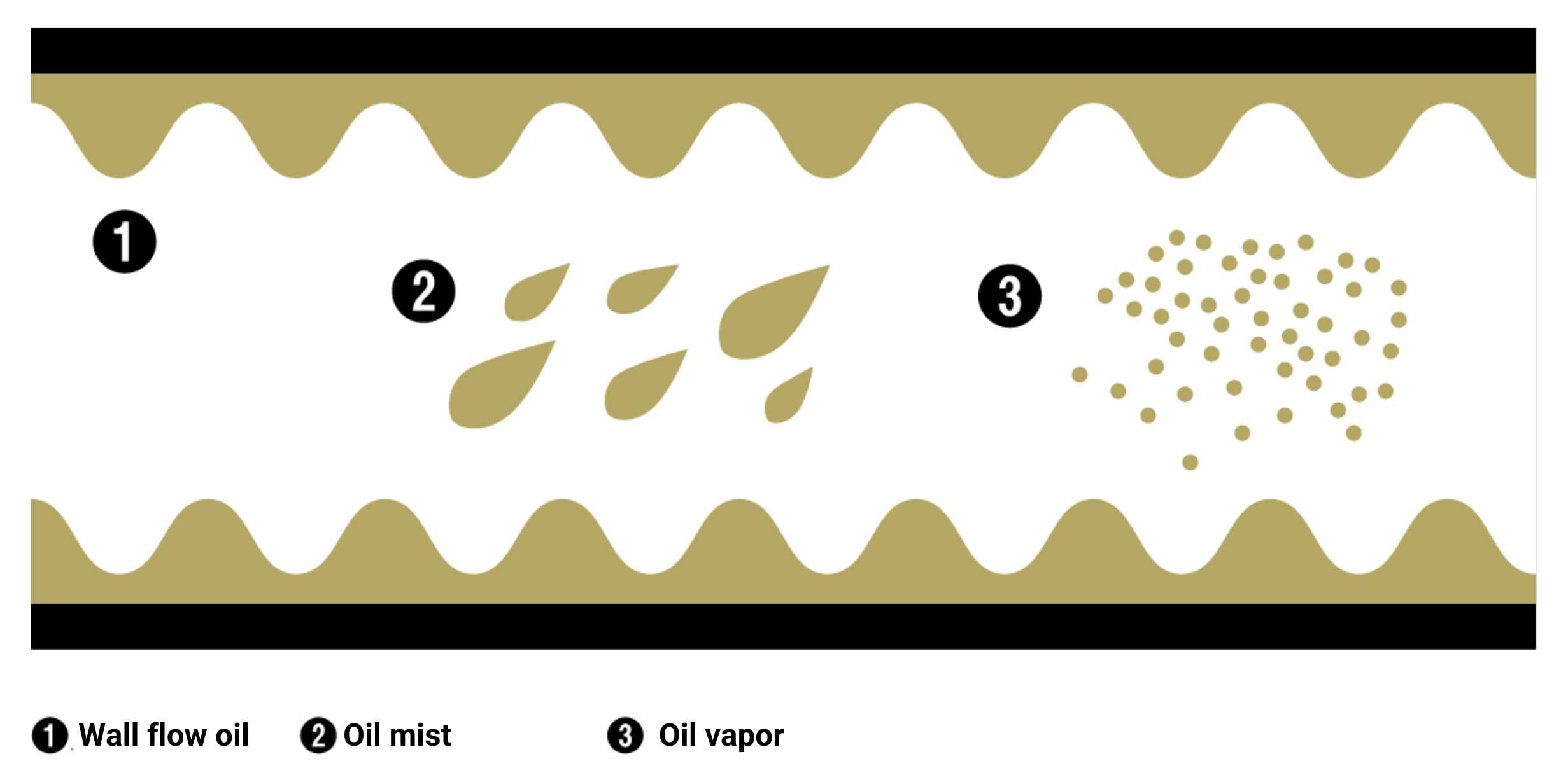

To qualify for Class 0 certification, compressed air must contain as little as possible of the following three elements: wall flow oil, oil mist, and oil vapor.

In particular, oil vapor cannot be removed by air filters, so a Class Zero compressor is extremely important for factories that require clean air.

※This is based on our research of oil-free scroll compressors for industrial use of 0.75 kW or more.

Let’s join our campaign! Answer the questionnaire to win prizes

ANEST IWATA SOUTHEAST ASIA Co., Ltd.

-1.png)